Coursework_California College of the Arts_MArch_Spring 2017

Instructors_Thom Faulders

We are no longer surprised by technology. With the mass inundation of today’s digital inventions, the promise of the tech revolution has arrived and has receded to the background of society. Now, as our offices, commercial spaces, and indeed our homes are tapped and bugged by “smart” gadgetry and virtual interfaces, the need and desire for an engaging the physical matter of architecture is at an all-time low. An opportunity for distraction back to the material world then resides in elevating the surreal presence of architecture’s banality. Through experimentation of architecture’s most unassuming surface (a characteristic certainly expressed in its slang label)—dry wall—we can challenge the drab, dry nature of today’s physical spaces and re-engage the value of architecture’s most prolific element—the wall.

Material Properties

Drywall is indeed just that, the most uninteresting architectural component. It’s dryness and homogeneity of applications has allowed it to permeate throughout our world unnoticed and widely considered a non-material. It is inherently rigid, flat, smooth, and thin—merely a surface for paint. Some practices have challenged these assumptions such as OMA’s exposed ceilings at the IIT Student Union Building or Erin Besler’s installation “The Entire Situation” that exposes drywall’s thickness as an architectural problem, yet none have truly explored the true materiality of this surface treatment.

In the construction world, drywall is certainly a physical material as its installation and manipulation must be performed with rough craftsmanship due to the difficulty of use. Being composed primarily of the mineral gypsum, sheet rock contains a significant mass and spatial presence as a building material as it is shipped and staged on a construction site. Contradictorily the massive nature of gypsum wall board vanishes after installation as it is applied across an expansive surface area and is concealed by layers of tape, joint filler, and paint.

As a manufactured sheet material, the properties of drywall as a layered assembly also pose valuable territory for challenging our assumptions of the on-material. The rigid core of gypsum is only able to remain stable by the adherence of paper backing on both faces. These paper finishes provide a smooth paintable surface as well a structural exoskeleton.

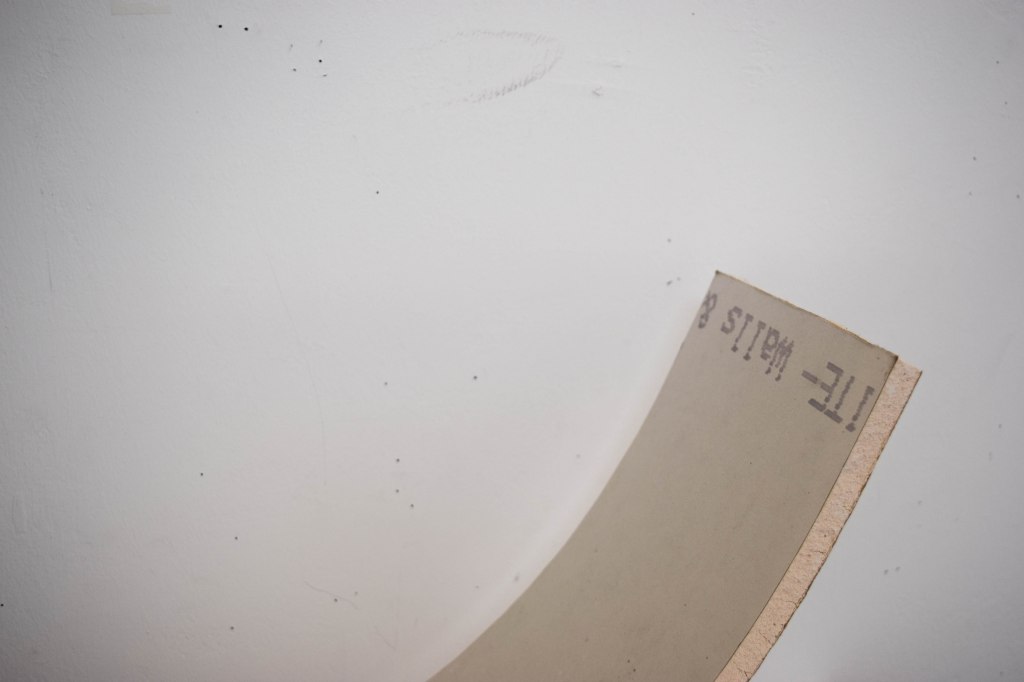

This project uses Steven Johnson’s theory of exaptation — “borrowing a mature technology from an entirely different field, and putting it to work to solve an unrelated problem”1 – as a method for exploring the material nature of drywall. Here the techniques of steam bending wood are exapted from furniture design trades. Originally developed as a method to bend wood stock into continuously curved elements for boat building, furniture design, and other industrial applications, the steam bending process has challenged our perceptions of wood’s material capabilities by manipulating its cellular structures. Considering drywall’s capacity to bend (roughly) when wet, this mock-up utilizes the added forces of heat and steam to develop a technique for cleanly and precisely bending the material.

1. Johnson, Steven. Where Good Ideas Come From: The Natural History of Innovation. Riverhead Books, New York, 2010, 153.

Material Advantages

This process advances the standard methods of achieving curved surfaces with drywall that typically involve a compromise of its structural facing by scoring and breaking the board. The roughly faceted curve is then excessively covered by the excessive layering of spackle and rigorous sanding. This new method of steam-bent gypsum board maintains both the structural integrity and finish clarity of the paper sheets allowing the material to uphold its rigid and massive form. Once the drywall is secured in its curved state, the surface of matter takes on spatial and structural quality of its own and survives apart from the previous requirement of wall framing as a support.

Material Disadvantages

While steam-bent drywall produces a smooth curvature of the paper facing without wrinkling or deterioration, once dry and rigid too much pressure against the curve can cause the paper to wrinkle if not handled correctly. The process of bending also requires a refined methodology in order to not break pieces or tear the paper finish and can be unpredictable at this early stage of refining the technique.

Scalability

At the current scale mock-up, this new level of craft in manipulating drywall could pull it into the disciplines of product and furniture design and is a reversal of the typical flow of inspiration between professions. Scaling up the size of the gypsum board sheet is theoretically only determined by the size of the steam box and bending jig and would still only require two workers for installation. Once the means and methods for larger sheets have been developed, the new material properties could be used to design new interior details and styles. These details would encourage the use of drywall as both a smooth surface and decorative ornamentation to confuse our previous understanding of the material.

Economic Projection

As a cheap readily available material that is relatively easy to install by two workers, this invented technique is inherently economical and efficient. Where the material of drywall itself is cost effective, the equipment for steaming and bending is also low-tech and low-cost. A simple garment grade steamer feeds into an insulated plywood box to generate the internal conditions for heating the material. The jig for bending can then be easily fabricated from medium density fiberboard, however geometric complexity is more difficult to achieve and may require specialized CNC manufacturing tools. The productivity in implementing steam-bent drywall as a material is found in the high quality effect that is produced out of its cheapness.

Material Distraction

The product of the curved surfaces presents the banal material in a surreal state counter to our available understanding. Forcing the drywall into a willful curve provides a new structural potential for the sheet material and jolts our reading of it as a composition of matter. Counter-intuitively, the curvature also reinforces our understanding of drywall as a non-material surface and even enhances its flexibility. Both material and object, tactile and abstract, regional and representational, the dry wall takes on new readings as an autonomous and crafted architectural element. This duality is akin to Michael Meredith’s explanation of today’s use of the various mediums of architecture in Matter: Material Processes in Architectural Production. Where Frampton’s regionalisms were once incompatible to Eisenman’s formalisms, Meredith asserts that these mediums for reading architecture are no longer discrete, specific mediums2. Steam Dry Wall subscribes to this notion as it manifests as an interface between our physical and virtual worlds. Materially, it is still obviously drywall, yet it is not dry, nor a wall.

2. Borden, Gail Peter, and Michael Meredith. Matter: Material Processes in Architectural Production. Routledge, New York, 2012, 9-15.